2025 Sanitary Pad Machine Investment Outlook (India Edition)

From market and compliance to Welldone’s “stable, fast, and traceable” specification

Website: https://www.cnwelldone.com | Mobile: 13655936189

01 | Why now: demand, cost, and compliance are all moving

- Demand:Asia–Pacific remains the largest and fastest-growing region; school distribution, public procurement, and retail move in parallel to form steady, year-round demand.

- Cost and freight:Wood pulp, superabsorbent polymer, and ocean freight show cyclical swings. That puts a premium on yield and fast changeovers.

- Bottom line:Pick equipment that turns macro uncertainty into stable qualified output, flexible format switching, end-to-end traceability, and a clear payback model

02 | Compliance direction: fluorinated substances, microplastics, and eco labels

- United States state lawsare tightening on intentionally added fluorinated substances in menstrual products.

- European Unionregulations on chemicals and eco-labels for absorbent hygiene products raise expectations for material choices and audit trails.

What this means for equipment

- stable adhesive application and dosing.

- lot and process traceability.

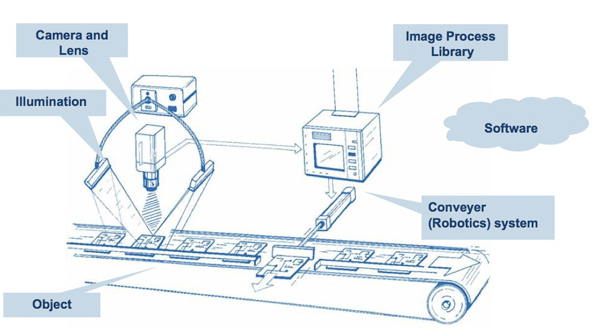

- one hundred percent inline vision, automatic rejection, and image logging. keep brand-selectable modulesfor adhesive and web guiding to match customer lists and certifications.

03 | Turning trends into specs: Welldone’s “stable, fast, and traceable”

- Speed and qualified rate:The full-servo sanitary napkin line is design one thousand pieces per minute and stable nine hundred pieces per minute. Typical acceptance targets include a qualified rate not less than ninety-eight percent by contractual scope, with low scrap. Carbon-fiber rollers and closed-loop tension improve registration, edge quality, and consistency.

- Automation to reduce cost:Automatic unwinding and splicing, tension control, and inline rejection shift operators from firefighting to optimization. Eight to ten people per shift can run the main line.

- Factory envelope:Main machine length twenty-eight meters, width five point five meters, height three point five meters. Recommended working space length thirty-nine meters, width nine meters, height five meters. Power demand about four hundred kilowatts. Compressed air zero point six to zero point eight megapascals.

- Formats and packing:The fast and easy packing route supports wing positioning and ninety-degree folding, plus bag or strip packing—one platform for school or public programs and retail.

Wide Vision Machine and Online Inspection

04 | Three investment tiers—how to choose what “adds up”

Full-servo high speed (flagship, for retail and export)

- For multi-SKU portfolios, dense orders, and tight price points. Stable nine hundred pieces per minuteplus high qualified output dilutes fixed cost and buffers material and freight volatility.

Value line (shaft and variable-frequency drive, stable five hundred to five hundred fifty pieces per minute)

- For regional brands and cost-sensitive channels focused on two hundred forty millimeters and two hundred ninety millimeters. Investment-friendly and simple to maintain—stabilize overall equipment effectiveness first, then scale or upgrade.

Entry lightweight (thin-core, two hundred fifty pieces per minute)

- For pilots, school and community programs, and local supply. Low barrier and fast deploymentto validate channels and assortments.

Transmission components

05 | Make the math obvious (India scene)

Channels and price bands (policy-driven)

- Pradhan Mantri Bharatiya Janaushadhi Pariyojana Suvidha pads:nationwide pharmacy network selling at one Indian rupee per pad for the oxo-biodegradable variant—ideal for universal access, public, and school distribution.

- Menstrual Hygiene Scheme:for rural girls aged ten to nineteen, six pads per pack at six Indian rupees, with decentralized procurement at state level.

Tax and compliance advantages

- Goods and Services Tax:sanitary pads are zero percent since twenty eighteen, improving affordability and throughput.

- Compliance:tightening rules on fluorinated substances and microplastics in North America and the European Union mean material traceability and inline image evidence matter even more for export and contract manufacturing.

Cost and freight guardrails

- Ocean freight remains sensitive to geopolitics and rerouting; budget scenarios should list transport separately for cross-ocean materials and finished goods.

- For illustration only, the currency conversion below uses one United States dollar equals about eighty-seven point four Indian rupees.

Monthly volume and payback formula

- Assume ninety-two percent uptime, twenty hours per day, twenty-six days per month:

- Six hundred pieces per minutegives about seventeen point two two million pads per month.

- Nine hundred pieces per minutegives about twenty-five point eight three million pads per month.

- Payback in monthsequals capital expenditure divided by (monthly volume times gross margin per pad minus fixed monthly operating expense)

- Illustrative currency conversion:

- Six-hundred-class linecapital expenditure about twelve million United States dollars, or about one point zero four nine billion Indian rupees.

- Nine-hundred-class linecapital expenditure about eighteen million United States dollars, or about one point five seven three billion Indian rupees.

- Fixed monthly operating expenseabout one hundred twenty thousand United States dollars, or about zero point one zero four nine billion Indian rupees.

Payback sensitivity under India price bands

“Gross margin per pad” below is the margin to the factory, not the government purchase price. If monthly volume times margin is less than or equal to fixed monthly operating expense, monthly profit is negative and the case is not recommended.

- At zero point five Indian rupees per pad:

- Ocean freight remains sensitive to geopolitics and rerouting; budget scenarios should list transport separately for cross-ocean materials and finished goods.

- For illustration only, the currency conversion below uses one United States dollar equals about eighty-seven point four Indian rupees.

- At one Indian rupee per pad:

- Six-hundred-class line: about fifteen point six months.

- Nine-hundred-class line: about ten point three months.

- At one point five Indian rupees per pad:

- Six-hundred-class line: about six point eight months.

- Nine-hundred-class line: about five point six months.

- At two Indian rupees per pad:

- Six-hundred-class line: about four point four months.

- Nine-hundred-class line: about three point eight months.

How to read this

- In public and universal-access channels (for example Janaushadhi and the Menstrual Hygiene Scheme), the end price is extremely low—often one Indian rupee per pad. Factories must rely on scale and qualified rateand any applicable subsidy clauses. If margin sits around zero point five to one Indian rupee per pad, the nine-hundred-class high-speed line is the practical choice; at one Indian rupee margin the payback is about ten point three months, while zero point five stretches too long and is generally not advised.

- In retail, private label, and export, one point five to two Indian rupees per padis common depending on formulation and packaging. Both six-hundred and nine-hundred classes drop into the three point eight to six point eight months short-payback window, closer to global norms.

- When superabsorbent polymer or pulp prices rise, or freight increases and the currency weakens, the flagship line’s higher qualified outputhelps defend unit cost. When public orders land, fast changeover and multi-SKU capability accelerate time-to-value.

India rollout checklist

- Dual-track strategy:use the nine-hundred-class flagship for retail, export, and large government orders; use the five-hundred to five-hundred-fifty-class value line for regional private labels and lower price bands.

- Lock compliance early:enable full-width inline vision, auto-reject, and photo logging, plus lot traceability to satisfy state and central procurement audits.

- Spell out tender parameters:design and stable speed, qualified-rate target not less than ninety-eight percent, process capability index Cpk not less than one point three three, overall equipment effectiveness, energy and air consumption; map Janaushadhi and Menstrual Hygiene Scheme scenarios into the changeover, format, and packing configuration.

06 | Quality and yield: fix the “top three” first

- Edges and registration:stabilize with servo phasing, closed-loop tension, and die-to-web alignment.

- Adhesive path and coat weight:control nozzle temperature, pressure, and path, plus surface-energy management.

- Core dosing and thin-core uniformity:use forming rolls and zoned compression with vision thresholds.

- With full-width inline vision, automatic rejection, and evidence logging, scrap can be held in the one to two percentband, per contract.

Transmission process

07 | Compliance-ready acceptance checklist

- Qualified rate:not less than ninety-eight to ninety-nine percent by contract; process capability index Cpk not less than one point three three on critical dimensions and registration.

- Traceability:material lots, vision images, reject logs, and QC records exportable, with connectivity for manufacturing execution systems and enterprise resource planning.

- Materials route:options for fluorine-free and low-residual adhesives and substrates to meet North American and European expectations.

08 | Why Customers Prefer Welldone Sanitary Napkin Machines

1.Available faster

Using a ramp-up method of “speed steps combined with a qualified rate window,” the design capability is quickly converted into a stable qualified output of 900 pieces per minute; online vision and automatic rejection reduce downtime; and eight to ten people per shift are sufficient to stably operate the main line.

2. Cost controllability and predictable unit economics

Under the stated raw-material and energy assumptions, higher qualified output dilutes fixed overhead and lowers unit manufacturing cost. Once you provide gross margin per pad, energy rates, labor cost, and primary SKUs, we will—under a single, consistent set of assumptions—deliver a three-chart decision pack: Speed—Unit Cost—Payback, with sensitivity notes to accelerate internal approvals and support external negotiations.

3. Agile changeovers, broad format coverage

The same platform supports 240mm, 290mm and thin-core routes; packaging paths such as wing-shaped positioning, 90-degree folding, and strip packing can be quickly switched to cover multiple scenarios of retail, private brands, and public procurement orders.

4. Quality consistency with an auditable evidence chain

Closed-loop tension control and carbon-fiber rollers stabilize registration and edge quality. Acceptance targets include a qualified rate not less than ninety-eight percent (per contractual scope) and a process capability index not less than one point three three for critical dimensions. Image logging and lot traceability are exportable for audits and retrospectives.

5. Clear facility envelope—plan once, execute once

Main machine: length twenty-eight meters, width five point five meters, height three point five meters. Recommended working space: length thirty-nine meters, width nine meters, height five meters. Power requirement: about four hundred kilowatts. Compressed air: zero point six to zero point eight megapascals. This clarity lets civil works and utilities be right-sized from day one.

6. Compliance readiness for international markets

Options for fluorine-free and low-residual material routes. Traceability and reporting integrate with manufacturing execution systems and enterprise resource planning—streamlining audits and tender submissions in North America and the European Union.

7. India-fit economics with a visible payback window

Tailored for public procurement and retail dual channels. Under illustrative assumptions, one Indian rupee per pad gross margin with stable nine hundred pieces per minute yields a payback of about ten point three months; actual results depend on contract scope, uptime, and site data.

Next steps

Send us your target gross profit per pad, energy and labor costs, main specifications, and site power and space. We will return a speed–unit cost–payback chart package and implementation roadmap based on a unified methodology—for internal review and external negotiations.

Conclusion | A device is also a set of methods for "stable production, cost control, and approval"

Welldone’s fully servo-powered sanitary napkin production line combines speed, quality, and traceability, while also offering fast order changeovers to meet diverse needs. Faced with the triple pressures of demand, cost, and compliance in 2025, this is the path to more stable operation and faster conversion.

Send us your target gross profit, material prices, and on-site power and space requirements.We’ll provide a set of three charts showing “speed, cost, and payback” for internal review or client roadshows.

Website: https://www.cnwelldone.com | Mobile: 13655936189