Complete Guide To Setting Up A Sanitary Pad Production Line

Setting up a sanitary pad production line can be a rewarding and profitable endeavor. This guide will take you through every step of the process, from understanding the market to scaling up your production. By the end of this article, you’ll have a comprehensive roadmap to launching your own sanitary pad production business.

The sanitary pad market has seen significant growth over the years. With increasing awareness of women’s health and hygiene, the demand for high-quality sanitary pads has soared. The global market is expected to continue expanding, driven by rising disposable incomes and improved access to feminine hygiene products. Understanding these trends is crucial for anyone looking to enter this market.

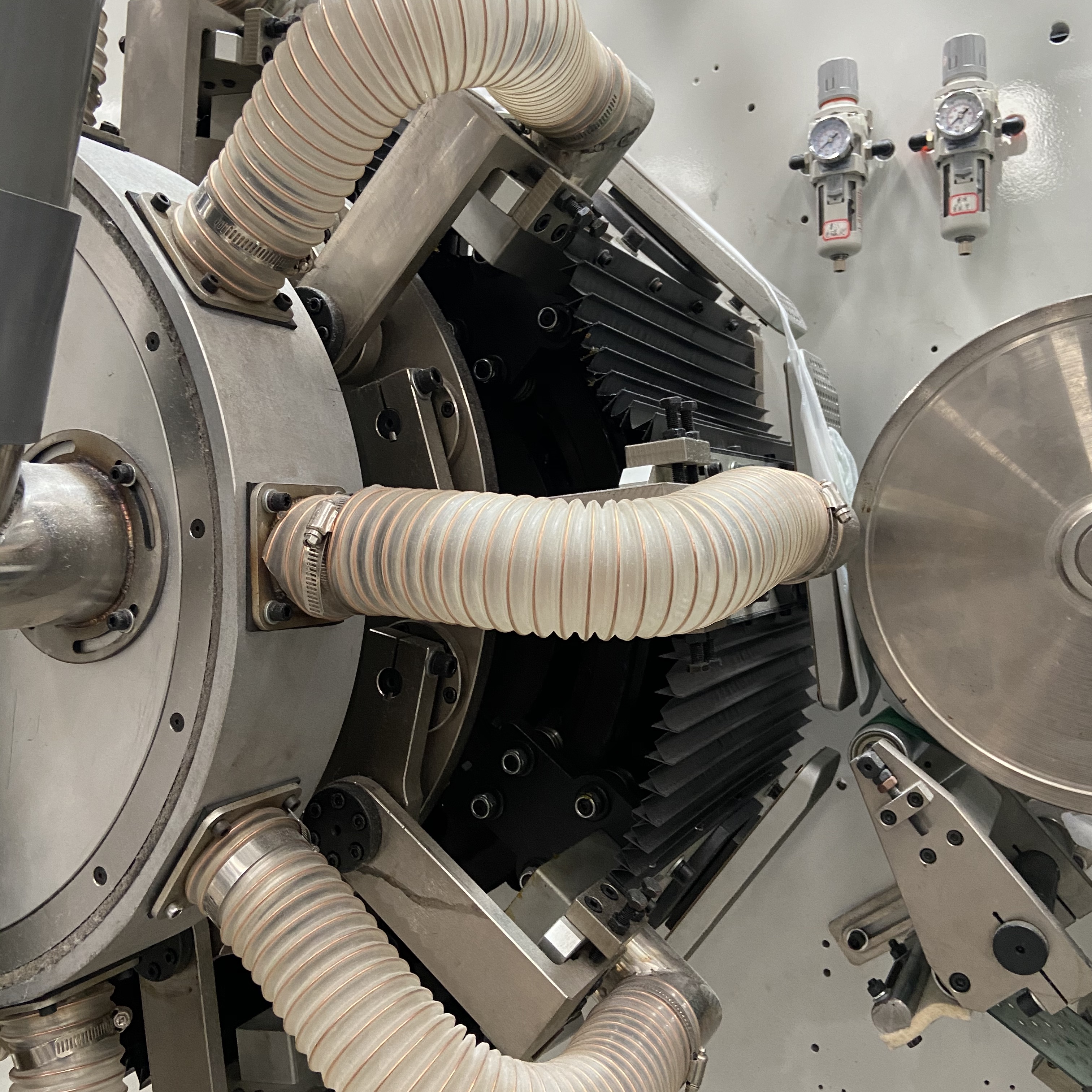

Sanitary Pad Making Machines

Choosing the right sanitary pad making machine is crucial for your production line. Different machines offer varying levels of automation and production capacity. Here’s what you need to know.

Types of Sanitary Pad-Making Machines

Sanitary pad making machines come in three main types: fully automatic, semi-automatic, and manual. Fully automatic machines are the most advanced, capable of producing large quantities of pads with minimal human intervention. These machines ensure high efficiency and consistency in quality.

Semi-automatic machines require some manual input but are still efficient for medium-scale production. They are a good balance between cost and efficiency. Manual machines, on the other hand, are suitable for small-scale production. They are the most affordable option but require significant labor and are less efficient.

Key Features to Look For

When choosing a sanitary pad making machine, consider the following features: production capacity, automation level, quality control features, and energy efficiency. Production capacity is crucial as it determines how many pads you can produce in a given time. Higher automation levels reduce labor costs and increase consistency.

Quality control features ensure that each pad meets your standards, preventing defects. Energy efficiency is also important as it impacts your operational costs. Investing in an energy-efficient machine can save you money in the long run.

Setting Up The Production Line

Setting up a sanitary pad production line involves careful planning and execution. From selecting the right site to installing and testing your equipment, each step is crucial.

Site Selection and Layout Planning

Selecting the right site for your production line is the first step. Consider factors such as proximity to raw material suppliers, access to transportation, and availability of skilled labor. The site should also comply with health and safety regulations.

Once you have selected a site, plan the layout of your production line. An efficient layout minimizes movement and maximizes productivity. Ensure there is enough space for all your equipment and that the workflow is smooth. Compliance with health and safety regulations is crucial to avoid legal issues and ensure a safe working environment.

Equipment and Materials Required

Setting up a production line requires various types of equipment, including sanitary pad making machines, packaging machines, and quality control instruments. Each piece of equipment plays a vital role in the production process.

You’ll also need raw materials such as absorbent core materials, top sheets, and adhesive strips. The quality of these materials directly impacts the quality of your sanitary pads. Ensure that all materials meet industry standards to produce high-quality products.

Installation and Testing

Once you have your site and equipment ready, the next step is installation. Follow the manufacturer’s guidelines to install each machine correctly. After installation, conduct thorough testing to ensure everything is functioning properly.

Testing procedures should cover the entire production process, from raw material handling to final product packaging. Identify and troubleshoot any issues before starting full-scale production. Regular maintenance and calibration of your equipment will ensure consistent product quality and prevent downtime.

Production Process Of Sanitary Pads

The production process of sanitary pads involves several steps, each critical to ensuring the final product’s quality and effectiveness.

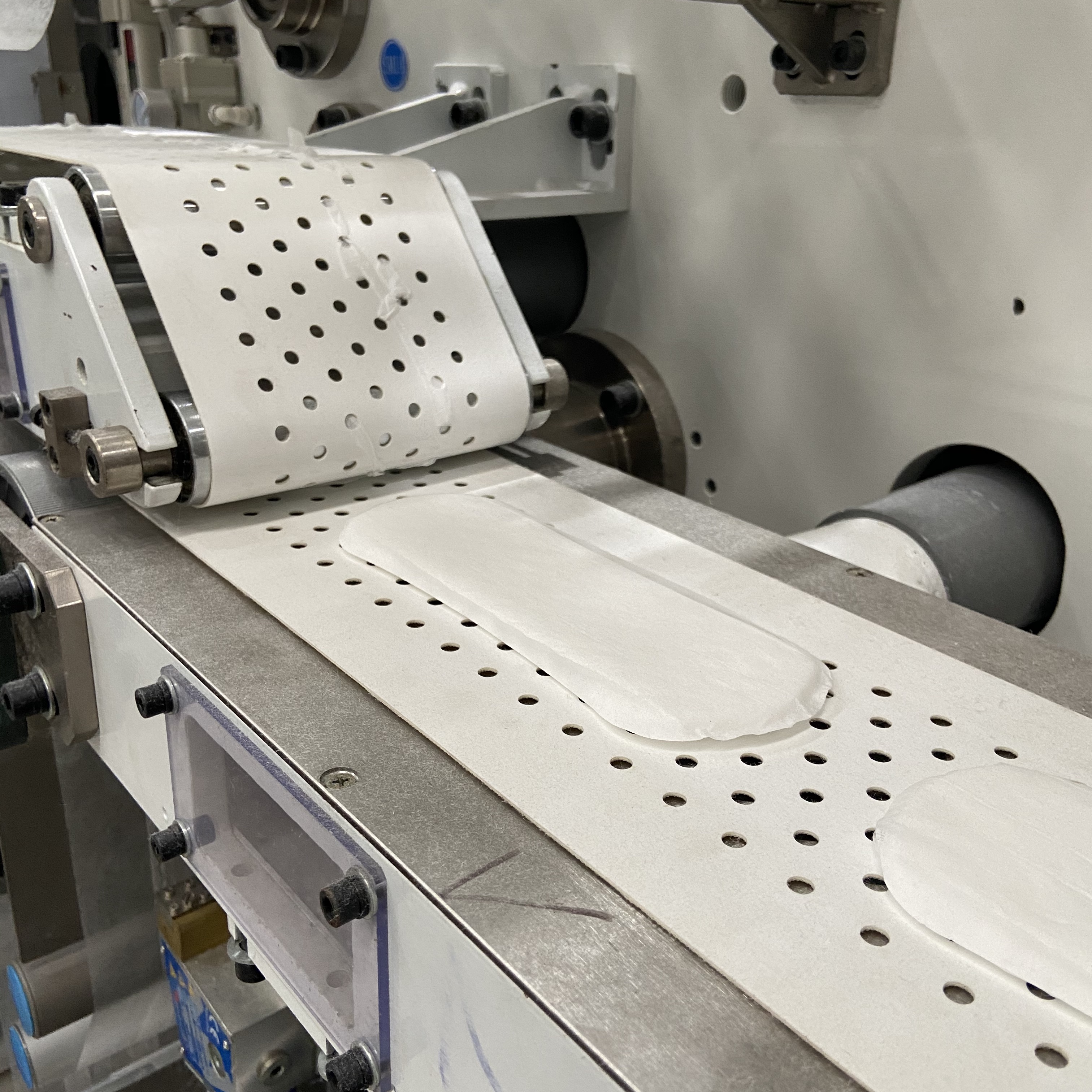

Step-by-Step Manufacturing Process

The manufacturing process begins with the preparation of raw materials. The absorbent core material is processed and cut to the required size. The top sheet and back sheet are then layered over the core, and adhesive strips are applied.

Each step in the process needs precise control to maintain product quality. Machines must be calibrated to ensure accurate cutting and layering. Quality control measures should be implemented at every stage to detect and correct any defects.

Packaging and Storage

Proper packaging is essential to protect sanitary pads from contamination and damage. Packaging materials should be durable and hygienic. Automated packaging machines can ensure consistency and efficiency.

After packaging, sanitary pads should be stored in a clean, dry environment. Proper storage conditions prevent product deterioration and maintain quality. Implementing a robust inventory management system can help track stock levels and manage supply chains effectively.

Regulatory And Compliance Requirements

Meeting regulatory and compliance requirements is crucial for any sanitary pad production line. Understanding and adhering to these standards ensures your products are safe and marketable.

Industry Standards and Certifications

Various international and local standards govern the production of sanitary pads. These standards cover aspects such as material quality, manufacturing processes, and product safety. Obtaining the necessary certifications demonstrates your commitment to quality and compliance.

Research the relevant standards in your target markets and ensure your production processes meet these requirements. Certifications from recognized bodies can enhance your brand’s credibility and consumer trust.

Health and Safety Regulations

Compliance with health and safety regulations is mandatory for any manufacturing facility. Implementing workplace safety measures protects your employees and ensures a safe working environment.

Provide regular training for your staff on safety procedures and the use of protective gear. Maintain high standards of sanitation and hygiene in your production facility to prevent contamination and ensure product safety.

Cost Analysis And Budgeting

A thorough cost analysis and budgeting are essential for the success of your sanitary pad production line. Understanding your costs helps in financial planning and ensures profitability.

Initial Investment and Setup Costs

Setting up a production line involves significant initial investment. Costs include purchasing equipment, setting up the facility, and obtaining raw materials. A detailed breakdown of these costs helps in planning and securing funding.

Consider various funding options such as loans, grants, or investor funding. Proper financial planning ensures you have the resources needed to start and sustain your production line.

Operational Costs

Operational costs include monthly expenses such as labor, utilities, raw materials, and maintenance. Understanding these costs helps in setting product prices and managing profitability.

Implementing cost-saving strategies can enhance your bottom line. Regularly review your expenses and look for areas where you can reduce costs without compromising on quality. Calculating return on investment (ROI) helps in assessing the financial viability of your production line.

Marketing And Distribution

Effective marketing and distribution strategies are key to the success of your sanitary pad production line. Reaching your target market and building a strong brand presence are crucial.

Developing a Marketing Strategy

Identify your target markets and understand their needs. Develop a marketing strategy that highlights the benefits of your products and differentiates you from competitors. Utilize various marketing channels such as social media, online advertising, and partnerships with health organizations.

Branding and packaging design are also important. A strong brand identity and attractive packaging can enhance product appeal and customer loyalty.

Distribution Channels

Choosing the right distribution channels is crucial for reaching your customers. Options include local retailers, wholesalers, and online sales platforms. Building partnerships with retailers and distributors can help expand your market reach.

Online sales and e-commerce platforms offer significant opportunities for growth. Setting up an online store allows you to reach a broader audience and provide convenient purchasing options for your customers.

Scaling Up The Production Line

As your business grows, scaling up your production line becomes necessary to meet increasing demand and expand your product range.

Expanding Production Capacity

Indicators that it’s time to scale up include consistent demand growth and production bottlenecks. Upgrading your equipment and technology can help increase production capacity and efficiency.

Consider investing in advanced machines and automation technologies to enhance productivity. Expanding your production capacity enables you to meet market demand and maintain product quality.

Diversifying Product Range

Introducing new products can help you tap into different market segments and increase revenue. Consider developing products that cater to specific customer needs, such as eco-friendly or premium sanitary pads.

Customizing products for different markets can also enhance your competitiveness. Conduct market research to identify opportunities for product diversification and innovation.

Conclusion

Setting up a sanitary pad production line is a multifaceted process, but it can be incredibly rewarding both economically and socially. Throughout this guide, we’ve walked you through every step necessary to launch a successful sanitary pad production business. From understanding market trends and selecting the right sanitary pad making machine to navigating regulatory requirements and scaling up production, each aspect plays a critical role in ensuring your venture’s success.

Establishing a sanitary pad production line not only meets an essential health need but also offers a profitable business opportunity. The market for sanitary pads continues to grow, driven by increased awareness of women’s hygiene and rising disposable incomes. By producing high-quality products, you can significantly impact women’s health while building a sustainable and lucrative business.

If you’re ready to embark on this journey, remember that thorough planning and attention to detail are key. Invest in the right equipment, adhere to industry standards, and develop effective marketing and distribution strategies. As you grow, continuously seek ways to innovate and improve your products.

For more detailed information and support on setting up your sanitary pad production line, visit our website at www.cnwelldone.com. We’re here to help you succeed in this essential and growing market.