From Raw Materials to Hygiene Solutions: How Sanitary Napkin-Making Machines Work

Why Sanitary Napkin-Making Machines Matter

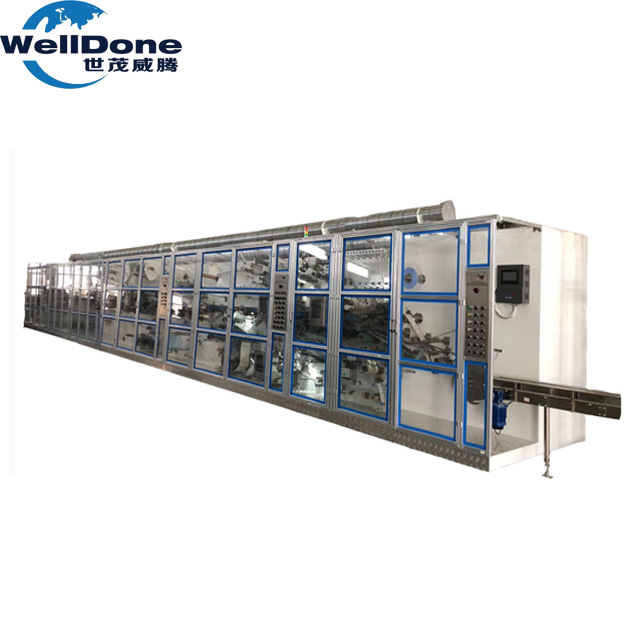

WELLDONE MACHINE CO.,LIMITED——Sanitary napkin making machine

The global menstrual hygiene market was valued at approximately $23.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030.

However, millions of women worldwide still lack access to affordable and hygienic menstrual products, especially in rural and low-income areas.

Sanitary napkin-making machines offer:

1. Cost-Effective Production: Lowering the cost per unit of sanitary pads.

2. Local Empowerment: Enabling small-scale manufacturing in communities.

3. Sustainability: Reducing dependence on imported products and enabling eco-friendly alternatives.

Core Components of Sanitary Napkin-Making Machines

Sanitary napkin-making machines vary by model and production capacity but generally consist of the following components:

Component | Function |

| Pulp Feeding Unit | Feeds raw absorbent material into the machine. |

Core Formation Unit | Shapes the absorbent core of the sanitary pad. |

| Sealing Unit | Bonds layers together for a secure structure. |

Cutting Mechanism | Cuts the pads into the desired shape and size. |

Glue Application Unit | Applies glue for securing the pad in place during use |

Packaging System | Wraps the finished product for hygiene and convenience. |

How Sanitary Napkin-Making Machines Work

1. Raw Material Feeding

The process begins with feeding raw materials into the machine. Typical materials include:

· Wood Pulp or Fluff Pulp: Forms the absorbent core.

· Non-Woven Fabric: Used for the top layer that contacts the skin.

· Polyethylene Film: Serves as the waterproof bottom layer.

· Adhesive Strips: Ensures the pad stays securely in place.

Modern machines are equipped with automatic feeders to minimize manual intervention, ensuring precision and efficiency.

2. Core Formation

The absorbent material, such as fluff pulp, is compressed into a specific shape to form the core of the sanitary pad. Some machines use advanced technology to distribute the material evenly, improving the pad’s absorption capacity.

3. Layering and Sealing

Once the core is formed, it is layered between the non-woven fabric (top layer) and polyethylene film (bottom layer). These layers are bonded together using ultrasonic sealing or heat sealing.

4. Cutting and Shaping

A cutting mechanism trims the pads into their final shape. Pads can be rectangular or contoured, depending on the machine’s settings and design specifications.

5. Adhesive Application

Adhesive is applied to the back of the pads, allowing them to stick to underwear during use. Machines often include an additional feature to attach wings for extra security.

6. Packaging

Finished pads are wrapped individually for hygiene and convenience. Machines may use biodegradable wrapping materials to promote environmental sustainability.

Production Capacities and Models

Sanitary napkin-making machines come in a range of models, from small-scale manual machines to fully automated industrial systems.

| Machine Type | Production Capacity | Suitability |

| Manual Machines | 200–500 pads/day | Small-scale operations, NGOs, startups. |

| Semi-Automatic | 240000+pads/day | Medium-scale production. |

| Fully Automatic | 400000+ pads/day | Large-scale commercial manufacturers. |

Fully automatic machines are more expensive but offer higher efficiency, better quality control, and reduced labor costs.

Sustainability in Sanitary Napkin Production

With growing concerns about environmental impact, many manufacturers are shifting toward eco-friendly production. Sanitary napkin-making machines now support:

1. Biodegradable Materials: Using bamboo fiber or organic cotton instead of synthetic materials.

2. Minimal Waste: Advanced cutting mechanisms reduce material wastage.

3. Renewable Energy: Solar-powered machines are being adopted in remote areas.

These efforts align with global goals for sustainability and reduce the ecological footprint of menstrual products.

Real-World Impact

Case Study: India’s Menstrual Hygiene Initiative

In rural India, non-governmental organizations (NGOs) have introduced manual sanitary napkin-making machines to empower women. These machines have:

· Created jobs for over 10,000 women.

· Reduced the cost of sanitary pads by 50% compared to commercial brands.

· Increased school attendance among girls by 20–25%, as affordable pads became accessible.

Corporate Social Responsibility (CSR) Programs

Large corporations are also investing in sanitary napkin-making machines as part of their CSR initiatives. For instance, a program in Kenya distributed machines to women’s cooperatives, enabling them to produce and sell pads locally.

Challenges in Implementation

While sanitary napkin-making machines offer significant benefits, challenges remain:

Initial Investment

Many small organizations struggle to afford advanced machines. Subsidies and grants can help bridge this gap.

Awareness and Training

Operating and maintaining the machines require proper training, which may not be readily available in remote areas.

Cultural Barriers

In some communities, taboos surrounding menstruation hinder the adoption of these machines. Awareness campaigns are critical to addressing this issue.

Future Trends

Smart Machines

Integration with IoT for real-time monitoring and inventory management.

Enhanced Efficiency

New technologies like 3D printing could revolutionize the production of sanitary pads, making machines faster and more versatile.

Localized Production Models

Expanding access in underserved regions through smaller, decentralized manufacturing units.

Conclusion

Sanitary napkin-making machines are transformative tools in the fight for menstrual equity. By turning raw materials into affordable and high-quality products, these machines empower communities, promote sustainability, and improve access to menstrual hygiene worldwide.

Whether for small-scale local initiatives or large-scale commercial production, these machines represent a critical innovation in addressing one of the most pressing health and social challenges of our time.

There is a soft luminosity to your writing, revealing meaning gradually. Each phrase invites careful observation, reflective consideration, and a meditative engagement with the text.

Thank you brother, your comments are my greatest support