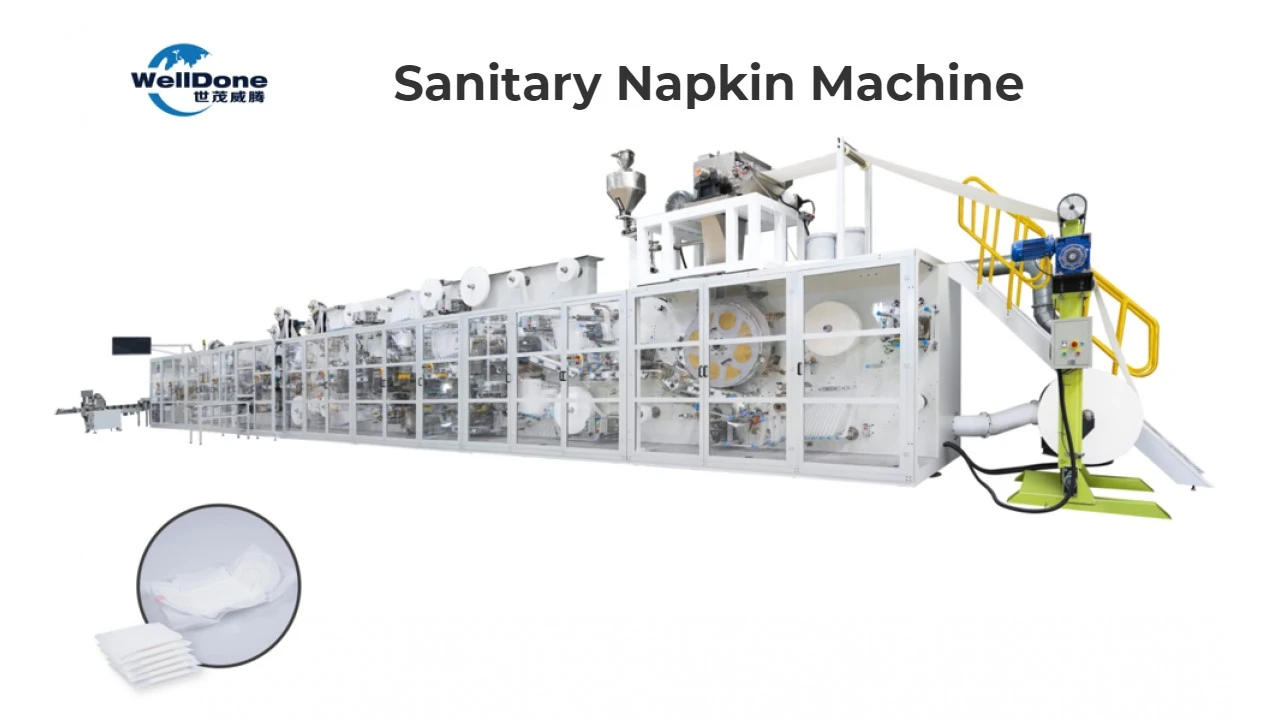

Welldone sanitary napkin new machine

Women Sanitary Napkin Machine Welldone sanitary napkin manufacturing machine, Proven production technology and excellent product quality are the benchmarks of our machines.Welldone a professional and experienced factory, we take “Quality First” as our working guideline, all majority parts of our production lines are purchased and processed according to the highest standards of the industry.we gained a great number of honours and awards from Chinese government and our customers both from domestic and overseas markets.

Sanitary Napkin Machine Introduction

Sanitary napkin is a sanitary product used by women during menstruation.sanitary napkin machine making the finished product called sanitary napkin,and also there are another called panty liner,sanitary napkin length is usually over 180mm,and panty liner is usually lower than 180mm,so normal there are 2 types different machine,one is sanitary napkin machine,the other is panty liner machine.from sanitary napkin package way,there are fast easy package type and strip type package type ,and if according to different drive system,they all can be divided into full servo machine,semi servo machine and frequency mechanic drive machine.

Our sanitary napkin machine’s highest speed can reach to 1000-1200pcs/min,and keep stable speed.

Q: How many years has your company been on the market?

A: We are focus on this hygiene industry filed already 15 years since 2008.

Q: What is the annual sales volume?

A: Usually our machine sales volume reach RMB100,000,000.00 it is about 20-25 sets machines each year, for another parts raw materials sales amount is about 80 million.

Q: Is there a quality management system such as ISO 9001?

A: We have approved ISO 9001 and CE Certification.

Q: Do you provide after-sales service support to suppliers?

A: Welldone Service Range:

1. Finished Product Design -Recommend suitable& competitive machine

2. Complete Hygiene Industry Management System Service:

A. Cost and Feasability Study

B. ROI (Return of Investment) Report

C. Production Factory Layout Plan

D. Material Planning Management

E. Warehousing Management Programs

F. After sales Service:

a. Installation service, b. operating machine, c. production team arrangement, d. non-scheduled service as per your requirement.

G. Quality Control System

H. Mechanical Failure Analysis System

I. Financial Analysis Programs for executive level